The intricate dance of products on shelves may seem mundane to some, but to us, it’s a symphony of data, design, and decision-making. Every planogram tells a story; when interpreted correctly, it can transform the retail experience. Today, we delve into the art and science of utilizing Blue Yonder Space Planning and category management best practices to uncover what your planograms might be telling you.

The Story Behind Every Planogram

Imagine walking through a store where every product is perfectly placed, each item easily accessible, and the aisles inviting you to explore more. This is the magic of effective space planning. But behind this seamless experience lies a robust process powered by data and strategic thinking.

When you look at a planogram, you’re not just seeing a layout of products; you’re witnessing a culmination of insights derived from sales data, consumer behavior, and market trends. For instance, why is a particular cereal brand placed at eye level while another is shelved lower? The answer lies in understanding consumer preferences and purchasing patterns. Eye-level shelves are prime real estate, often reserved for high-demand products or those with higher profit margins.

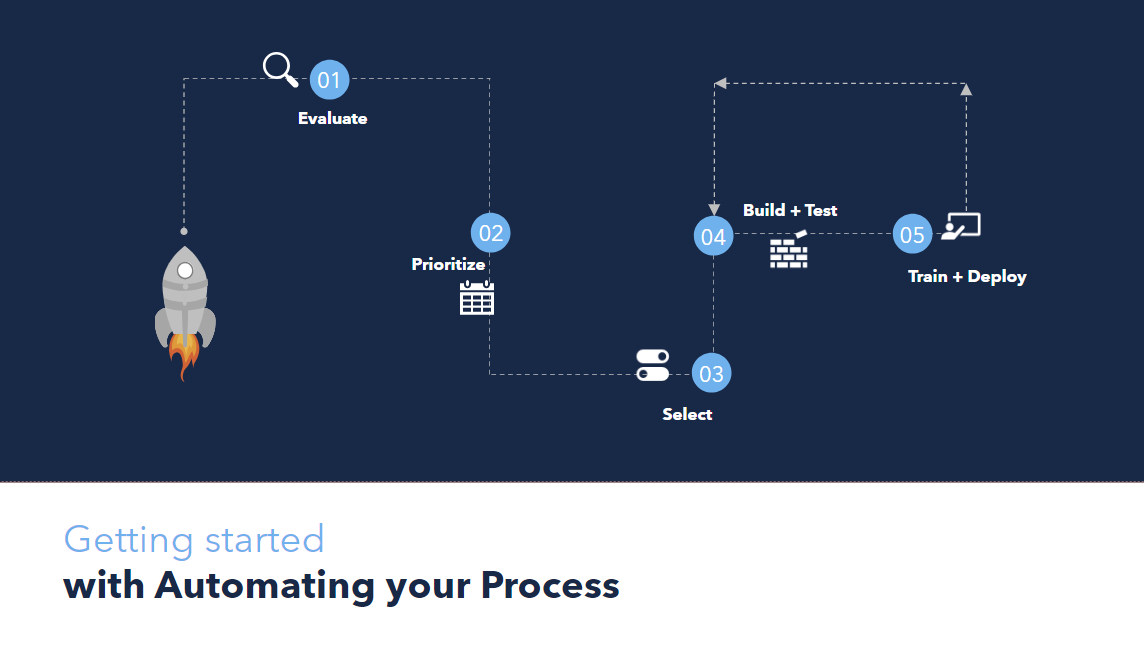

At Cantactix, we use Space Planning and MissionControl’s automation capabilities to decode these preferences and create planograms that speak to both the retailer’s objectives and the customer’s needs. Are you wondering, what is MissionControl? It’s a proprietary tool designed to work seamlessly with Blue Yonder Space and Floor Planning. It helps automate repetitive tasks, ensuring accuracy and efficiency. This powerful tool allows us to visualize and design product placements that optimize space, enhance the shopping experience, and ultimately drive sales.

Listening to Data

The real magic happens when we start to listen to what the data is telling us. Each sales report, customer feedback, and market analysis is a piece of a larger puzzle. Blue Yonder Space Planning software excels at aggregating this data into meaningful insights. It’s like having a conversation with your store layout, where each data point adds a new dimension to the story.

Let’s say, for example, we notice a decline in the sales of a top-performing product. By analyzing the planogram data, we might discover that the product has been moved to a less prominent shelf. The software helps us visualize this shift and understand its impact. With this insight, we can quickly rectify the situation by repositioning the product to a more favorable spot, thus reviving its sales performance. Advanced analytics capabilities allow us to predict future trends and adjust our strategies accordingly. This proactive approach ensures that we’re always one step ahead, ready to meet changing consumer demands and market dynamics.

Common Supplier Problems

Common problems faced by retail manufactures include inconsistent processes, delays, and quality checks. Most problems can be solved by utilizing automation and standardized workflows, allowing teams to overcome these challenges effectively.

Does your team have any of these problems?

- Rule Breakers: The team doesn’t follow a consistent process, which leads to issues.

- Delays: Your category team is always behind due to buyer changes or supply chain issues.

- Quality Checks: Your quality checks take forever and aren’t always accurate.\

- Skill Level: Your team only has one or two Space Planning pro users and high turnover.

- Real-time Metrics: Inability to track KPIs and make decisions as I’m building planograms.

- Training: We struggle with getting new employees up to speed and working with new tools.

- Retailer Process: Your planograms are often rejected because they aren’t compliant with retailer specifications.

- Time Management: My team doesn’t have time to test or focus on merchandising strategies.

Poor planning also accounts for many reoccurring yet solvable problems. Remember the old adage, “Work smarter, not harder?” Sometimes, you need to take a step back and reevaluate your processes. From data import to planogram validation, proper tools and planning will save time and reduce manual errors. MissionControl, for example, can help alleviate the pain of data entry and monotonous tasks and allows you to view planogram analytics in real-time, facilitating better decision-making.

Root Cause Analysis

If you’ve made it this far, you are either thinking, “Okay, we are on target; this doesn’t give me anxiety.” or “Wow, things are worse than I thought!” If this all sounds out of the realm of possibility, slow down and consider where the root causes might lie. Are any of the following true?

- Are your processes separate? Documentation of necessary steps is outside of the applications they are working in, meaning an additional step to get things done.

- Does your team not see the value? Tenured team members sometimes think they know all the steps and don’t need to check the documentation.

- Are your processes outdated? Maybe your processes have changed but the documentation hasn’t, so people ignore it all.

MissionControl is not just about making tasks easier; it’s about transforming the way you work. By automating repetitive tasks, ensuring data integrity, and providing real-time metrics, it enables category managers to focus on strategic decisions rather than getting bogged down in manual processes. This leads to better store execution, improved compliance with retailer specifications, and more efficient use of resources. Learn how Danone cut their relay time in half, by utilizing the automation available in MissionContol, giving them time back to focus on the future and dig into the data to grow their share of shelf here. Cheers to not working holidays or weekends anymore!

Continuous Dialogue

Effective space planning is an ongoing conversation. It’s about continuously monitoring, learning, and adapting. Space Planning supports this dialogue by offering real-time analytics and feedback mechanisms. As soon as a planogram is implemented, we start collecting data on its performance. Are customers engaging with the displays as expected? Are there any bottlenecks or overlooked opportunities?

For instance, one of our clients, a major retailer, faced challenges with inconsistent execution of planograms across different stores. By leveraging automation, we identified specific areas where the planograms weren’t being followed correctly. This insight allowed us to provide targeted training and support, ensuring that each store could replicate the intended layout accurately. This continuous feedback loop helps us refine our strategies and improve our processes. It’s a dynamic interplay where each iteration brings us closer to perfection, ensuring that our planograms not only meet but exceed expectations.

We believe that every planogram has the potential to transform retail space. By combining the power of Blue Yonder Space Planning with our expertise, we unlock these stories, turning data into actionable insights and strategic decisions. We invite you to discover the difference that effective space planning can make. Whether you’re looking to optimize your current layouts or embark on a complete redesign, our team is here to help you every step of the way.

The Takeaway

Understanding what your planograms are telling you and utilizing the right tools can drive significant improvements in your space planning practice. Join us on this journey to efficiency and excellence with Cantactix. Ready to transform your space planning process and unlock the full potential of your planograms? Contact us to learn more about how Cantactix can help you achieve your goals and supercharge Space Planning to meet your specific category requirements!

With the latest MissionControl update, users can tackle even more challenges with streamlined, problem-solving features that enhance efficiency across planograms. Need to quickly update product placements? The Swap Anything tool now includes a Swap Products option, allowing you to replace one product with another seamlessly, retaining all positions, orientations, and merchandising styles. Struggling with mirrored planograms that have swapped product pairs? The new Swap Positions feature makes it easy to transpose product positions, keeping your layout accurate and intuitive. And when adding products to fixtures, the Add Positions function in Add Anything helps you pinpoint exactly where products should go. For Walmart users, the Prepare Modular for Drawing feature lets you effortlessly transfer positions from existing planograms to new builds, enhancing the drag-and-drop process. Ready to see MissionControl live? Request a demo today!