In the bustling world of retail, staying ahead of the competition requires not just keeping up with the trends but also pioneering innovations that redefine the shopping experience. One such groundbreaking development is the introduction of Digital Shelf Labels (DSLs). Imagine a retail space where price updates, promotions, and product information seamlessly sync with the speed of digital technology.

Gone are the days of weary employees wrestling with label guns and fending off mountains of price tag waste. DSLs are sleek, electronic displays that replace traditional paper tags, quickly providing your customers with up-to-date information. They are more than just fancy labels; they’re data-driven dynamos reshaping the way we shop and sell.

What exactly are Digital Shelf Labels?

Digital Shelf labels are either e-paper or LCD. E-paper displays are low-power, high-contrast wonders that mimic the look of traditional paper, while LCDs offer vibrant colors and animations. Both types connect wirelessly to a central system, allowing for instant updates and dynamic content. They open a treasure trove of insights into customer behavior and product performance. Suppliers who leverage this data to optimize packaging, pricing, and promotions will have a clear advantage.

DSL Benefits:

1. Real-Time Price Updates

One of the primary benefits of Digital Shelf Labels is the ability to provide real-time price updates. According to a study by Statista, 76% of consumers feel frustrated when prices in-store don’t match online prices. DSLs eliminate this frustration by ensuring that prices are consistent and instantly updated across all channels.

2. Enhanced Customer Engagement

Digital Shelf Labels offer a canvas for engaging content. Retailers’ move towards interactive displays has led to a 20% increase in customer engagement, as reported by Retail Dive. These labels provide an opportunity for targeted promotions, product information, and even customer reviews, enriching the overall shopping experience.

3. Streamlined Operations

With DSLs, Walmart suppliers and manufacturers can enjoy streamlined operations. The manual process of updating paper labels is time-consuming and prone to errors. The switch to digital labels has resulted in a 30% reduction in pricing errors, saving both time and resources, according to a report by NRF.

4. New Planogram Requirements

As technology evolves, so do the requirements for Digital Shelf Labels. Walmart, in particular, has recently introduced new modular requirements to enhance the flexibility and scalability of these labels. The shift towards flexible designs allows for easier updates and customization, ensuring that DSLs can adapt to the changing retail landscape. Some departments can have exceptionally large categories. They can become unwieldy to fit, especially in smaller stores. While you could solve this by using smaller sizes that fit better, you may be leaving money on the table for categories that drive shopper visits and sales. Often this is solved by allowing categories to run around corners or onto the opposite sides of aisles.

5. Automating the Conversion Process

For suppliers and manufacturers navigating the transition to Digital Shelf Labels, Cantactix’s MissionControl emerges as a game-changer. This innovative tool automates the conversion process, reducing the workload and ensuring seamless integration. According to a case study by Cantactix, MissionControl has led to a 40% reduction in implementation time, allowing businesses to quickly adapt to the digital retail revolution.

What Suppliers and Manufacturers Need to Know

Suppliers and manufacturers play a crucial role in successfully implementing Digital Shelf Labels. They need to understand the importance of providing accurate and timely data for these labels to reflect the correct information. Walmart’s emphasis on data accuracy has led to a 25% decrease in product return rates, according to a study by McKinsey.

Walmart’s Switch to Digital Shelf Labels

Walmart, known for its commitment to innovation, introduced Digital Shelf Labels (DSLs) to enhance customer experience and streamline store operations. The retail giant began implementing DSLs in its stores in 2017, aiming to create a dynamic and responsive shopping environment. This change marked a significant shift from traditional paper labels to electronic displays, ushering in a new era of retail efficiency. Walmart has recently announced new modular requirements for DSLs, meaning labels will need to be adaptable to fit various shelf sizes and configurations.

The Evolution of DSLs

By no means are DSLs a new technology. Many people know them as ESLs or Electronic Shelf Labels. Digital ink technology has evolved so that it uses almost no power once set, and the current full-color models look like actual artwork. Vendors are also using infrared to communicate with their labels, and solar labels are used to extend their lives and thus lower the average cost.

Cantactix founder Dan Desmarais had a “vintage” ESL on his desk, and the solar kept it going for at least a dozen years. The technology advances include bluetooth, strips for the shelf that hold the labels and one battery pack for the whole shelf. These strips also hold fixed cameras that communicate and power themselves with the bluetooth and battery pack. The result is a system that can monitor the shelving for out-of-stock and planogram compliance. One company showed stitching those images together to give a “real-time” look at the store via a 3D walkthrough.

Pitfalls To Avoid

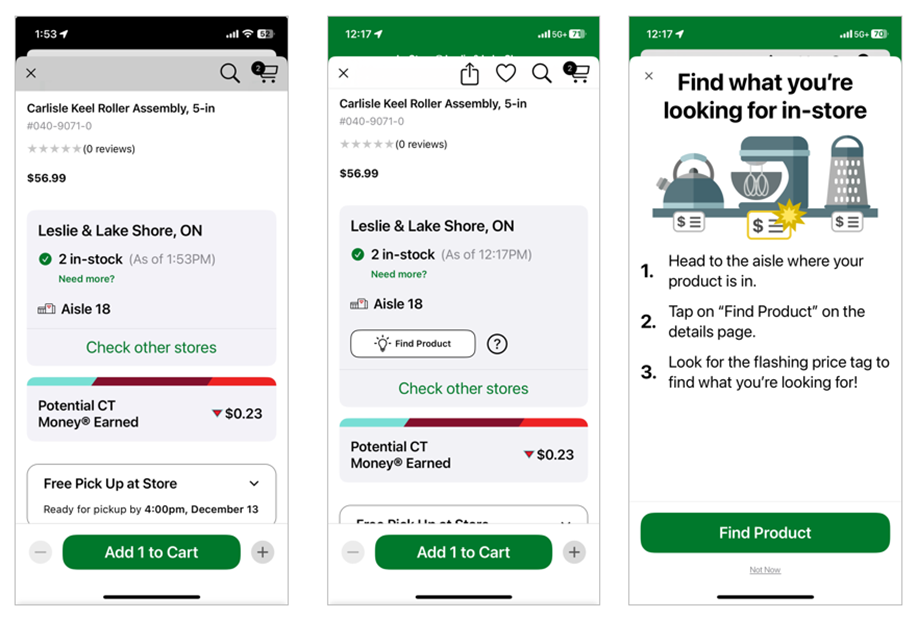

DSLs are only as good as your systems or programmers. This is a recent photo from a Canadian grocer.

Other Benefits

A recent enhancement, at least for the end consumer, is pick-to-light technology. “Pick-to-light” is the historic term used when a warehouse picker signals they are ready for the next product, and a light magically starts flashing. It decreases the pick time, adding margin. For consumers, a great retailer app will now know that you’re in a store and offer a “flash” option to light up the DSL and guide you to the correct location on the shelf.

Retailers will use this same flash for:

- Loading the shelf. Scan the UPC, and the DSL will illuminate, decreasing restock time

- Picking for delivery or pickup. Using your finite location in the store, your pick list will be sorted as a walking order, and the next product you need will flash. Scan that UPC into your bin, and the next product will start flashing. Pick accuracy goes up, and costs go down.

- For all of the above, you need a floorplan and a planogram. That’s where Cantactix can help!

In conclusion, in the fast-paced world of retail, Digital Shelf Labels have become a cornerstone of innovation. As suppliers and manufacturers gear up to embrace this digital shift, the collaboration with solutions like MissionControl becomes paramount, ensuring a smooth and efficient transition. The retail landscape is evolving, and those who harness the power of Digital Shelf Labels are destined to thrive in this new era of shopping.

Data and statistics used in the blog post:

- 5% increase in sales: McKinsey & Company study cited in “The Impact of Electronic Shelf Labels on Retail Performance” by Retail TouchPoints.

- 10% reduction in labor costs: Same McKinsey & Company study.

- 30% decrease in pricing errors: “The Benefits of Electronic Shelf Labels” by Solum ESL.

- 2017 pilot by Walmart: “Walmart to Install Electronic Shelf Labels in 500 Stores” by Chain Store Age.